New EPA report makes a compelling case for prevention in the U.S., where the majority of food gets wasted at the point of consumption. Source: Why We Can’t Afford To Waste Food | BioCycle Read More…

Auto Added by WPeMatico

New EPA report makes a compelling case for prevention in the U.S., where the majority of food gets wasted at the point of consumption. Source: Why We Can’t Afford To Waste Food | BioCycle Read More…

Nearly all Americans—90%—report that they throw away food after its “sell by” or “use by” date, believing that consuming it after the date will make them sick. However, most food is wholesome, edible, and safe long past the date on …

Continuing to demonstrate its commitment to sustainability, Amazon has introduced new insulated food packaging that is curbside recyclable. Source: Amazon Reduces Waste with Recyclable Insulated Food Packaging Read More…

Whether it’s a cap on production or a market mechanism, it’s likely to meet industry opposition. Source: Beyond reusing and recycling: How the US could actually reduce plastic production | Grist Read More…

DIVE Source: Cutting meat, produce and cereal waste would have greatest environmental impact: EPA | Food Dive Read More…

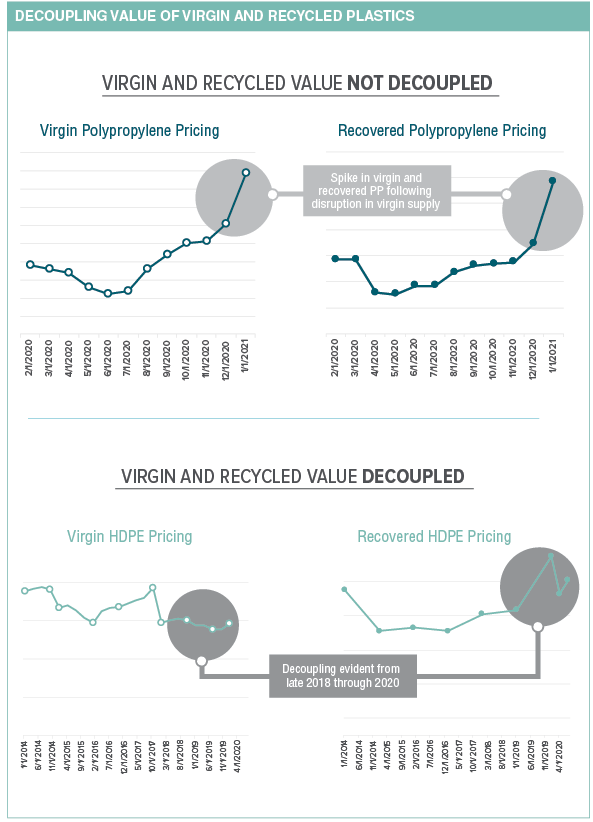

Historically, recycled plastic resin and bale prices have closely tracked virgin resin pricing. High virgin resin prices create good times for plastic reclaimers. Conversely the remarkably low virgin resin prices experienced across most plastic types in the last few years …

With new funding and award recognition, the Chicago-based startup's goals include quantifying the savings from reuse and having more large enterprises adopt its platform. … Read More…

The third quarter of the year brought a resilient recovered fiber export market, even as the largest overseas buyer virtually disappeared. Meanwhile, scrap plastic exports continued a precipitous decline.→ Source: Paper exports stable despite Chinese market exit – Resource …

More than 4 billion solar panels will be at the end of their useful lives by 2050, and little has been done to allow for the recycling of the panels. The materials recovered from the panels could potentially be valued …

The topic of advanced recycling continues to draw interest as the plastics crisis remains at the forefront of discussions among scientists, governments and media. A new report from Closed Loop Partners titled, “Transitioning to a Circular Syste … Read More…